Alcoholic beverages

Beverages

•

Alcoholic Beverages

·

Beer

·

Wine

·

Spirits

•

Non-alcoholic beverages

·

Flavoured beverages

·

Hot Drinks

·

Coffee

·

Tea

·

Other drinks

•

Chocolate based

•

Soft Drinks

·

Carbonated beverages

·

Fruit/vegetable juices

·

Bottled water

·

Functional Drinks

·

Ready-to-drink concentrates

·

Ready-to-drink teas

Beer production

a) Malting

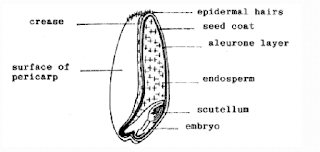

Malt is

barley that has been persuaded to germinate by soaking in water and has then

been dried by the application of heat .

The

“Steeping” or soaking period in the tank is usually 2 to 3 days.

The

water is drained off and the grain spread out to a depth of 20–30 cm on a

concrete or tiled floor in the malting house.

The

water content of the barley rises to approximately 43% by this soaking or

steeping process. Barley begins to germinate on the malting floor and generates

energy that raises the temperature. The barley must be turned every 4 or 6 h in

order to maintain approximately 168C temperature and to prevent growing roots

tangling each other.

After 7

to 10 days, the growing stem of the barley becomes one-half to five-eighths of

the length of the seed .

To stop

the germination, green malt is transferred to the drying

kiln, which has a unique

chimney

The floor of the kiln is a drain board made of perforated iron or wire mesh. The green malt is spread on this floor at a depth of 70 cm to 1 m, depending on the design of the kiln, and dried in smoke rising from a peat fire below the floor .Besides peat, coal and coke are often used as fuel and the barley is dried for 40–55 h until the moisture content becomes 3–4%.

.

b) Malt Milling

•

By milling malt, the starchy endosperm will become

better accessible for the malt enzymes and this will improve the extraction

process.

•

The selected milling technique depends on the methods

of mashing and separation that are used.

•

Milling should be performed in conditions that

preserve the structure of the husks when a lauter or mash tun is used, as in

this case the husks are needed to build up the filtration bed.

•

The husks are more elastic and will be less damaged

during milling when they are more humid. Therefore, the malt is usually made

humid (called “conditioned” or “wet” milling) before

it is milled. Dry or wet milling is performed in a roller mill.

Type of Milling

•

Dry milling

•

Wet milling

•

Milling with Conditioning

Dry milling

Roller

and hammer mills can be used for dry grinding. Rolling mills operate by passing

the malt through the narrow gap between pairs of closely spaced rotating rolls

Oscillating

(frequency of 6–12 Hz) sieves perform the separation steps.

Wet milling

§

The moisture content of the husks can be raised to 20%

by keeping the endosperm nearly dry in a hot water conditioning mill. This

process is referred to “hot water

conditioning”

§

In this case, the endosperm is squeezed from the husk

through a single pair of rolls.

§

After milling, mashing water is immediately added. The

quantity of conditioning water depends on the malt quality, degree of

modification, and achieved steeping degree.

Milling with Conditioning

§

In this process, the malt is moisturized with cold or

hot water, or steam. Moist husks are more pliable and will be less damaged in a

roll mill.

§

The temperature inside the kernel may not exceed 40 °

C to avoid damage to the enzymes. The total water content increases by about

0.7%. This corresponds to an increase in water content of the husks of 1.5–1.7%

and 0.3–0.5% of the endosperm.

§

The effect of the conditioning results in an increase

of the husk volume of about 10– 20%, an easier separation of the grist and

husks fraction, an increase in filtration rate in a lautertun, an increased

yield and attenuation, and a faster starch degradation.

c) Mashing

§

Mashing starts with mixing the grist and brewing water

(called “mashing-in”).

§

Hydration enables the malt enzymes to become active.

Today, mashing-in is part of the milling process, where it is performed in the

milling equipment. Typically, 2–4 hL

water is used for 100 kg malt, depending on the selected brewing method and

density of the produced beer.

§

During mashing, the malt content is solubilized by

making use of the enzymes of the malt and the extract is obtained . The mashing

operation will influence the alcohol content of the beer, the concentration of

unfermented sugars in the beer, the peptide and amino acid profiles of the

wort, the yeast nutrient concentration, the buffering capacity and pH of the

wort and beer, the b-glucan content of the beer, and some beer physical

properties such as foam, color, and clarity.

Mashing Methods

§

Mashing is performed in a mashing vessel (also called

mashing tun, mash mixer, or mash converter):

Ø

45–50° C for proteolysis and b-glucan

degradation;

Ø

62–65° C for

maltose production (b-amylase);

Ø

70–75° C for saccharification (a-amylase); and 78°

C as the final mash temperature to inactivate the carbohydrate enzymes and fix

the amount of fermentable sugars

Two types of mashing methods:

•

Infusion Method

• Decoction Method

Infusion Method

§

In infusion processes, the entire mash is heated up

(with appropriate rest periods) to the final mashing temperature.

§

Infusion methods can be classified as increasing

temperature (German infusion method) and decreasing temperature (English

infusion method) infusion processes (Fig. 20.3 shows some examples).

§

A classical German infusion method starts with a rest

period at 45–50 ° C (proteolysis) for 30 min. Next, the temperature is raised

to 62–65 ° C and kept at this temperature for 30–45 min (b-amylase). The next

rest period is at 70–75 ° C until complete saccharification (a-amylase). The

process ends at 78 ° C.

§

In the English

infusion method, the temperature is initially raised by adding hot water to the

mash. This method requires well-modified malt, because a part of the active

enzymes are destroyed by the addition of hot water. An alternative English

method is to perform the conversion processes at a single temperature, usually

63–65 ° C (“isothermal infusion mashing”). These English infusion methods are

used for the production of ales (top fermentation), where both mashing and wort

separation take place in the same vessel (O’Rourke 1996).

§

The advantages of the infusion method are that this

process can be easily automated and controlled, and energy consumption is

20–30% lower than for the decoction method (Kunze 1999). Disadvantages are the

rather worse iodine reaction and the possibly rather lower brewhouse yield

Decoction Method

§

In decoction processes, the temperature is increased

by moving part of the mash from the mash converter to the mash cooker where it

is boiled (possibly also with carbohydrate rest periods in the mash

cooker).

§

By pumping it back to the remainder of the mash in mash converter, the temperature of the

total mash is increased to the next higher rest temperature. The decoction

method is traditionally used in Germany for the production of lager beer.

§

Depending

on the number of boiled mashes, decoction methods can be classified as single-,

two-, and three-mash processes. Today, only the single- or two-mash processes

are used. The three-mash process consumes a lot of energy and is only used for

the production of some special beers.

The removal and boiling of the boiled mashes have

the following effects:

•

Less protein breakdown in the boiled mash because of more rapid heating;

•

More extensive gelatinization and saccharification of the starch;

•

Increased extraction of the husks;

•

Increased formation of melanoidins (Maillard reaction);

•

Increased removal of dimethyl sulfide

(DMS);

•

Reduced amounts of active enzymes in the total mash; and

•

Possibly a higher brew house yield

Mashing schemes

Increasing infusion mashing

Two mash decoction process.

Enzymatic Degradation Processes

•

Starch Degradation

•

Cell Wall Degradation

• Protein Degradation

Starch Degradation

§

Starch

is degradated by alpha- and beta-amylase, limit dextrinase, maltase, and

saccharine.

§

Gelatinized

starch is needed for beta-amylase in order to degrade starch efficiently.

§

The

complete degradation of starch to maltose and dextrines by amylases is called

saccharification.

§ Starch breakdown must be monitored because residues of undegraded starch and dextrins cause starch hazes in beer.

Cell Wall Degradation

·

Cell walls are essentially composed of b-glucan

and hemicellulose.

·

Cell wall degradation starts during malting and

continues during mashing by endo-b-glucanases, b- glucansolubilase, and

endo-xylanase

·

An insufficient degration of high-glucan

molecules results in a high viscosity and can give problems during wort and

beer filtration

·

An insufficient degradation of pentosans

(hemicellulose) can result in filtration and haze problems.

Protein Degradation

§

Protein

degradation products influence fermentation and beer flavor (lower molecular

weight (MW) degradation products), palate fullness (amino acids and higher MW

degradation products), color (Maillard reaction), and beer foam (higher MW

degradation products).

§

A

too extensive proteolysis gives bad foam, too dark color, poor palate fullness,

but a good colloidal stability. During malting and mashing, 35–40% of the total

protein content is degraded.

§

The

enzymatic breakdown of proteins occurs predominantly at 45–55 ° C, but does not

stop even at higher temperatures.

d) Wort Separation (Lautering)

§

During

the lautering process (also called “wort separation” or “mash separation”) the

un-dissolved substances are separated from the wort.

§

The

insoluble part (spent grains) consists of the husks, the seedlings, and other

insoluble material.

§

Wort

separation is a filtration process. As much of the extract as possible should

be recovered during lautering.

§

The

extraction efficiency is measured as “extract yield”, which is the ratio of the

mass of extract to the mass of malt or malt and adjunct.

§

The

filtration can be performed in a lautertun or a mash filter. Developments in

wort separation, which have been introduced over the last 15–20 years

e) Fermentation

Yeast is added in liquid or solid form to the wort

and fermentation takes place at 17–35 ° C for 48 h (on average).

The inoculated yeast converts maltose into glucose,

and then alcohol and carbon dioxide (CO2) are produced from glucose.

Yeast also produce small amounts of other compounds

such as a wide range of esters, aldehydes, acids, and higher alcohols. Many of

these are flavor elements. The fermented wort (wash) is a sweet peaty beer-like

liquid with an alcoholic content of 7–8%.

f) Filtration

This is to remove yeast which

otherwise continue the process of fermentation.

g)

Pasteurization

For beer making, the filtrate needs to be heat treated to destroy

pathogens before bottling. Beer is packaged in dark bottles or in amber, to

prevent light destruction of the beer.

**Types of whiskey: scotch, grain and blended

whisky

h) Distillation

Done in onion-shaped stills (pot stills), which are large copper kettles with narrow necks called lyne arms or lyne pipes that curve and enter the condenser, often located in the open air outside the still house .Copper dissolves easily and has a decisive influence on the quality of the spirit, as it removes sulfury or vegetable aromas by a chemical reaction

i) Maturation

The casks are secondhand, in that they have been used to store either sherry or bourbon, and in rare cases port or other wines.

Maturation of new spirits is conducted in casks stored in warehouses called “dunnage” warehouses for at least three years undisturbed. After that they can be legally called scotch whisky.

j) Bottling

**Wine may be defined as a fermented beverage prepared from grapes after alcoholic fermentation. When other fruits are used for preparation of wine then these are called by prefixing the name of fruits for example plum wine, peach wine etc. Wines are of two kinds viz. dry and sweet.

Dry wines contain practically very little or no sugar, whereas sweet wines contain some sugar and taste sweet. The alcohol content of these wines ranges from 7 to 20 percent. The wines are also categorized on the basis of alcohol contents as Light, medium or strong wines

Different types of wines.

|

Type |

Characterization |

|

Champagne |

It is made chiefly in France with certain varieties of grapes.

Champagne is a sparkling clear wine and also made in several other countries.

Generally the fermentation is allowed to proceed to completion in bottles.

These bottles are specially made to withstand high pressure of gas produced

during fermentation. |

|

Port |

This is fortified sweet red wine originally in Portugal, but now

produced in other countries. |

|

Muscat |

It is prepared from Muscat variety of grapes in Australia,

California, Italy and Spain |

|

Tokay |

It is famous fortified wine of Hungary |

|

Sherry |

Sherry is a Spanish wine, which is matured by placing the filled

barrel in sunlight having a temperature of 54 to 60oC for 3 to 4

months |

|

Perry |

The wine prepared from pears is called as Perry. It can be prepared

from the culled fruits and fruit trimmings of the canneries. |

|

Orange wine |

Sweetened orange juice is fermented to produce orange wine. The

method of preparation is similar to that of grape wine. Orange peel oil

should be minimum in the juice, otherwise its presence stop the fermentation

completely. |

|

Berry wine |

The wine made from fruits like strawberry, blackberry and elderberry

is known as berry wine. |

|

Feni |

Feni is a wine made from fermentation of cashew apple, in some places

like Goa. |

|

Nira |

Nira is prepared from the juice of the palm tree |

Comments

Post a Comment