Cereal technology

The main cereal crops: wheat, maize rice

WHEAT

Classification of

wheat

i)

Botanical species:

Tritichum durum

Tritichum compactum

Tritichum aestivum

ii)

Hardness of wheat

|

Hard wheat |

Semi-hard wheat |

Soft wheat* |

||

|

Strong flour |

Durum flour |

Semi-strong flour |

Pastry flour |

Weak flour |

|

Bread making |

Pasta processing |

Bread making |

Pastries |

|

Kenyan variety: soft wheat

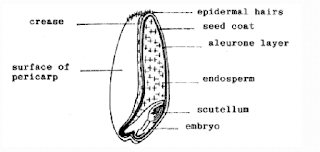

Wheat kernel

The three main parts: germ (embryo), endosperm and bran.

The bran is the outermost layer and has a protective

function. It has the aleurone layer.

The germ lies at the basal of the grain and is rich in

vitamin E and lipids.

Endosperm contains starch and proteins.

Longitudinal section of a wheat kernel (Spurway, 1988) :

Wheat milling

The primary aim of milling wheat: separate completely the bran and the germ from the endosperm to flour fineness hence maximum flour extraction

Break flour grading produces

first, second and third flour.

Separation and cleaning

There is removal of mixed

cereals, dirt, chaff, small stone and iron. The miller uses the milling

separator, magnetic separator, washer, screening machine and sieve in order to

remove them.

Blending

The wheat forms are blended to

yield flour of desired protein content according to the purpose of using.

Tempering and conditioning

Tempering is the process of conditioning wheat by the adding

or removing of water. Its aim is to:

·

Toughening the germ and bran since the toughness

of bran also increases progressively with moisture content. The bran is tougher

than the germ and the endosperm. The germ is pliable due to high oil content;

when the germ contains the right moisture it is flattened by narrow spaced

rolls and removed by sifter.

·

Making the endosperm more friable thus it can be

ground easily into particles

Therefore, tempering’s primary aim is to separate the germ

and bran from the endosperm.

The upper limit of moisture is 19% hard wheat and 17% soft

wheat. Excessive moisture causes flaking and makes it difficult to grind.

After tempering, wheat is kept for 20-40 hours to accelerate

diffusion of moistire to endosperm and germ

Break system

The tempered wheat is taken to a series of grinding

operations. Aiat consist of 5-6 sets of corrugated iron rolls and sifter. The

corrugated rolls/break rolls revolve in different speeds. The corrugations on

the roll become finer and the clearance of both rolls is closer.

·

The friable endosperm is separated from tough

bran and pliable germ. Material from the first break rolls is divided into five

groups:

·

Coarsest fragment: proceeds to the second break

rolls

·

Medium sized fragment: also called middling,

consists of the endosperm and carried to the next step, purification

·

Finest material: best flour called the break

flour

·

Germ

·

Bran

Purification

Middlings have the endosperm with small amounts of the germ

and bran. The germ and bran are removed by the sifter.

Reduction system

Middlings are reduced with smooth rolls also called

reduction rolls. It also has a system of smooth rolls and sieves thus producing

middling flour and gray short (bran, endosperm, germ particles)The ratio of

production form the wheat kernel in the extraction rate. An increase in

extraction rate leads to an increase in ash content.

WHEAT FLOUR

COMPOSITION

Figure 1: different

types of wheat flour and their respective standards.

Protein

The chief proteins are gliadin, glutenin, globuline and

albumine. Gliadin and glutenin are important in making bread since when mixed

with water they form gluten. Gluten helps to form a dough which can retain gas

evolved during fermentation

Carbohydrates

The main carbohydrates are: starch, dextrin, cellulose, free

sugars and pentosans. The refined flour has starch with small amounts of dextrin

and sugars.

In bread making, damaged starch has the following roles:

·

Form sufficient fermentable carbohydrates. The

damages starch is attacked by enzymes alpha and beta amylases to form maltose.

Maltose is broken down to carbon IV oxide by maltase and zymase in yeast

·

Contribute water absorption

·

Produce dextrin during baking to produce taste

Lipids

Generally, lipids are 1-2% in flour, 8-15% of the germ and

5-7% bran. Lipids are made up of bound lipids (phospholipids) and free lipids. Phospholipids

react with proteins during dough mixing to form a lipo-protein system for gas

retention. Fatty acid composition of the wheat lipids are palmitic, stearic,

oleic, linoleic and linolenic.

Minerals

The ash content of wheat: potassium, sodium, magnesium,

calcium, sodium.

Enzymes

The enzymes present:

alpha and beta amylase, protease, lipase, lipoxydase, ascorbic acid

oxidase and dehydrogenase.

BREAD MAKING

INGREDIENTS

Yeast exists in three forms:

·

Compressed yeast

·

Active dry yeast for bread making

·

Dry yeast is dormant and requires a

pre-fermentation step in warm water for 15-30 minutes.

|

Ingredient |

Function |

|

Yeast |

Fermentation and respiration |

|

Yeast food |

·

Supply nutrient to yeast ·

Decrease pH value of the dough ·

Provide oxidants such as potassium iodate,

ascorbic acid. They make the dough tough by oxidizing SH bonds to SS bonds ·

Improve the quality of water by using Ca2+

that can be used to adjust water hardness. |

|

Salt |

Provide flavor Prevent the dough from fermenting at an erratic rate Strengthen gluten |

|

Water |

Primary ingredient in mixing and dissolution |

|

Sweetening agents |

Give flavor and color through Maillard reactions Provide nutrients Provide sweetness Fermentation regulator Give softness to final product |

|

Shortening agents such as butter, margarine and lard |

Give shortness and crispiness to biscuits Tenderness to bread Help the dough become big in the oven Improve eating quality Stabilize cake batters Improve the keeping quality Give the nutritive value Give flavor to products |

|

Milk |

Increase the nutritive value (protein, vitamins and calcium) Help in the buffer action |

|

Emulsifier An example of an emulsifier: eggs has lecithin |

Retard retrogradation Increase the volume of bread Make tender crust, finer grain and smooth texture Give nutritive value and flavor Increase the volume of cakes Give good grain and texture to cake Give good color |

DOUGH PREPARATION

Types of mixers

Horizontal mixers:

has a big capacity and is used for mass production.

Vertical mixers: has a small capacity.

Functions of mixers:

·

Form homogenous mixtures of all ingredients

·

Help the gluten develop physically

·

Produce the desired characteristics of

plasticity, elasticity and viscous flow.

The developed dough has the following characteristics:

·

Surface has smooth appearance

·

When extended thinly, a thin membrane

Dough development

Chemical development

Dough is a complex viscoelastic system that forms a 3D

polymer network. The long polymer protein chains link together by several kinds

of binds: disulfide bonds, salt bonds, ionic hydrogen bonds, hydrophobic

interactions, and van der Waal and cross linkages. Gluten becomes longer

through the interaction between SH and SS bonds. The number of disulfide bonds

increase with the presence of oxidants and oxygen in air.

Stages in dough

development:

·

Initial or pick up stage: incorporation of

dough’s ingredients. The mass is slack, wet ad sticky thus the structure starts

to be formed.

·

Clean up stage: hydration almost finishes as

elasticity starts to develop. The walls of the mixer bowl are left clean. At

this stage, the dough has the strongest elasticity and cohesion.

·

Let down stage: developed dough is mixed

continuously; it reduces the elastic and cohesive properties and becomes a soft

mass.

·

Break down stage: gluten structure is

disintergrated completely. Dough changes to a slack and non-elastic mass.

Mixing time for the dough depends on the quality of dough

and rest of the ingredients, mixers speed, and temperature, stiffness of dough

and point of salt addition

Method of mixing dough

Sponge and dough

This method has a preferment stage called the sponge which has:

50%-80% of the total flour, all yeast, yeast food, 55-60% water of the flour

weight.

Mixing time is at low speed for 3 minutes and medium speed

for 1 minutes. The mass of sponge is considerably stiff and its temperature 23

– 25 C.The sponge is left in the fermentation room (27 – 29 ) for 3.5 to 4.5

hours. After fermentation, the sponge n=and the rest of the ingredients except

the shortening.

Steps:

-

Put 50-80% of total flour, yeast, yeast food and

water into the mixer bowl

-

Start to mix for preparing the sponge

-

Ferment the sponge at 27-29 for 3.5 – 4.5 hours.

-

Add the rest of the ingredients except

shortening into the matured sponge

-

Start to mix for preparing dough

-

Give the dough a floor time after mixing

-

Dividing section

Advantages:

-

Save the quantity of yeast

-

Give good texture and grain to final products to

retard staleness

-

Possess great flexibility

-

To make it possible to produce uniform final products

Straight dough method

This is a single step process where all ingredients are

mixed together at the same time. Dough temperature ranges from 25.5 – 28 with a

time range of 2 – 2.5 hours.

Steps:

-

Put all the materials into the mixer bowl

-

Start to mix: Start with the low speed for 1-2

minutes then change to medium speed. The use of low speed prevents the mixer

from scattering the materials.

-

Add the shortening agent after cleaning up stage

because the shortening requires hydration

-

Stop mixing as the dough forms a thin semi-transparent

membrane.

-

Ferment the dough

-

Divide section

Advantages:

-

Reduce the processing time, labor, power and

equipment requirements.

-

Reduce fermentation loss

-

Give good flavor to final products

FERMENTATION

Fermentation means micro-organism breaks down organic

material producing carbon IV oxide, alcohol, amino acids, esters, organic acid

…etc.

Functions of fermentation:

·

Production of fermented products: alcohol (ethyl

alcohol), organic acid (acetic acid, succinic acid, butyric acid), ester (ethyl

ethanoate) and carbonyl compounds (aldehydes, ketones).

·

Oxidation of the dough produces web structure

and a bigger capacity.

·

Gluten is swelled with heat and acids produced

by yeasts giving extensibility and elasticity.

Yeasts have enzymes that break down sugars: if there are

inverted sugars in the dough, it first consumes glucose and while in a mixed

sugar (glucose, fructose and sucrose), yeast consume first glucose then

fructose. Yeasts do not have enzymes to break down lactose thus they take part

in Maillard reaction.

Acidification

Wheat flour has acetic acid bacteria and lactic acid

bacteria. Lactic acid bacteria act on

glucose to produce lactic acid and acetic acid bacteria acts on ethanol to

produce acetic acid. The acids produced lower the pH and provide a good

environment for yeast enzymes at pH 4-5.

The reduction of Ph influences hydration, swelling of

gluten, enzyme activity and oxidation-reduction process.

Temperature

The amount of gas produced is dependent on dough

temperature. At 38 C, there is maximum generation of gas.

Osmotic pressure

If the concentration of sugar and salt are more than 10% and

2% respectively, they inhibit fermentation.

Generation and

retention

Factors of increasing gas production:

·

High concentration of yeast

·

Appropriate concentration of sugar

·

Proper amount of yeast food

·

High temperature of 38 – 40 C

·

pH value: 4-5

Factors that decrease gas production: high osmotic pressure,

low temperature

Fermentation room

Conditions of fermentation room: temp of 27-29 C since the

yeast has not prevailed yet against other micro-organisms under this

fermentation. Final proof: 38-40 C since the yeast has already spread

throughout the dough. The relative humidity is about 75-80%. If less, it will

cause the dough dry and retard fermentation.

Condition of sponge and the dough: proper fermentation

produces bread of better quality, better grain and big volume.

Over-fermentation produces bread of uneven grain and coarse texture while

under-fermented produces large, thick cell walls in bread.

Punching for straight dough method: equalizes the

temperature throughout the dough, removes the excessive carbon IV oxide and

introduces atmospheric oxygen. Punching involves pushing the dough to remove

gas from the dough. Fold the sides of the dough into the center. After 60% of

the total fermentation takes place, the dough is punched.

MAKING UP

This consists of dividing / scaling, rounding, bench time,

degassing/ sheeting, panning and final proof.

Dividing or scaling: cut the fermented dough into pieces of

desired weight.

Rounding: the aims of

rounding are make uniform the dough pieces in shape that vary in shape after

dividing and make continuous skin on the dough pieces.

Bench or intermediate proof: rounded dough balls have a

brief period of relaxation of 15-20 minutes at 27-29 C. Dough pieces recover

their pliability which was lost at dividing and rounding. If they do not relax

sufficiently, the gluten will tear easily during the next sheeting process.

Molding/ sheeting/rolling: the aim is to produce bread with

even grain and thin membrane.

Panning: involves putting the molded dough into a pan or

tray. The seam of dough is put on the bottom of the pan to prevent its seam

from opening during baking. The relation between pan volume and dough weight is

at the rate of 3-4.

Final proof: if the

panned dough is baked immediately, final product is small, dense grain and

small texture. In order to have good bread, the panned dough is left in the

fermentation room called the final proofer at 35-45 C and 75-80% RH. Excessive

moisture cause moisture condensation and cause blistering on the surface.

Proofing influences the bread properties: color of crust, texture and

graininess.

BAKING PROCESS

The baking stages:

·

First stage lasts for 6 minutes, carbon IV oxide

produced to achieve maximum loaf expansion. Crumb temperature increases by 4.7

C per minute.

·

Crumb temperature increases by 9.7 per minute

·

Final color, firmness is developed to the side

walls of the loaf (lasts 6 minutes)

Baking reactions:

i.

Oven Spring

The dough placed in the oven eventually springs up in the

oven. This caused by the following factors:

·

There are numerous gas cells in the dough. The

gases expand and increase in pressure

·

Some generated carbon IV oxide is soluble in the

dough. Higher temperatures reduce gas solubility and heighten the interior

pressure in the cell.

·

Higher temperature produces vapor from liquids

with low boiling point; this vapor also expands the cell walls

·

Higher temperature stimulates yeast activity and

produces carbon IV oxide dramatically.

ii.

Starch gelatinization and gluten coagulation

Starch gelatinization involves the swelling of starch at 54

C and finishes at 85-95 C. The degree of gelatinization depends on the water

availability.

Gluten coagulation starts at 74 C and loses its affinity for

water.

Color and flavoring reactions by Maillard reactions

CAKES AND BISCUITS

Ingredients:

1.

Cake flour: must yield a soft gluten thus not

developing a tough dough whilst cake mixing.

Desired protein content: 7-9% for cake and biscuits (11-13%

for bread making).

Chlorination is done at 300-1500ppm followed by benzoyl

peroxide treatment. This process leads to : lowering the pH and mellowness of

gluten.

2.

Eggs have the following action: binding action,

leavening action, tenderizing action, flavor and nutritive value.

3.

Baking powder (sodium bicarbonate, acid reacting

agents and ammonium bicarbonate): used for cakes and biscuits. Its functions

are: give good volume, improve the eating quality due to the tenderizing effect

on the crumb. Excessive use of baking powder produces a bitter taste to final

products.

![]() NaHCO3

+ acid reacting agent CO2

NaHCO3

+ acid reacting agent CO2

4. Icing,

spices and flavor

Method of various cake making

Sugar batter method (creaming method):

Fats (shortening and margarine)

and sugar are mixed to form a sugar-fat material.

Eggs must be gradually added into

sugar-fat to make water in fat emulsion. If eggs are added rapidly a fat in

water emulsion is made.

Flour and the rest of the

ingredients are added into the batter. The dough temperature is best between

15-17 C

The dough is put into the pan with

paper and baked at 150-160 C.

Flour batter

Fats and flour are mixed together

until a fluffy mass is obtained.

Eggs and sugars are whipped until

a semi-firm foam results

Sugar fat foam is combined with

the fluffy mass of fats and the flour.

The rest of the ingredients are

added and incorporated.

Single stage method

All the ingredients are mixed

together in a single step.

Method of biscuit making

Stamped type biscuit

Once the dough is mixed, it is sheeted by rollers and cut by

rollers into various shapes.

Drop type

biscuits

The dough is made soft, put into a hopper and the dough

comes out through the nozzle which has different shapes

Wire cut biscuits

The dough is put into the hopper, comes out through the die

and then cut to desired length with a wire.

Baking: it should be done and dried on hot tray after being

removed from the oven. Excessive grease on the tray causes unexpected spread of

the biscuit.

BREAD SPOILAGE

Staling is the progressive deterioration in quality.

Crust staling: the crust is relatively dry, brittle, and

crisp in its fresh form but becomes soft, leathery upon staling producing a

hard texture. This is due to the transfer of moisture from the interior of the

loaf to the crust.

Crumb staling: marked by softening of texture. The crumb

becomes brittle. Changes of crumb staling causes loss in flavor, moisture and

becomes brittle, hard.

The mechanism of staling is due to the retro-gradation of

starch.

MAIZE MILLING

Varieties of maize/corn: dent corn, flint corn, pop corn,

sweet corn, waxy corn, pod corn. It consists of tip, hull, germ, part of hard

and soft starch.

Wet milling

Wet milling produces a range of products including starch,

oil and various types of cattle feed.

Steeping

Cleaned maize is steeped in water, containing 0.1–0.2%

sulphur dioxide, at 50 _C for 28–48 h. The steeping softens the kernel and

facilitates separation of the hull, germ and fiber from each other. The SO2 may

disrupt the -SS- bonds in the protein, enabling starch/protein separation.

Concentration

After steeping, the steep water is concentrated by vacuum

evaporation

Settling to recover

protein

The protein it contains is recovered by settling.

Course milling

The steeped maize is coarsely milled in a Foos Mill .The

grain is cracked open and the germ released.

Germ recovery

The germ is recovered by settling or by means of

hydrocyclones. Oil may be extracted from the germ by pressing.

Fine milling

The degermed material is strained off from the liquid and

milled in an impact or attrition mill.

Separation

The hulls and fibre are separated from the protein and

starch by screening. The suspension of starch and protein coming from the

screen is fed to high-speed centrifuges where they are separated from each

other.

Starch purification

The starch is purified in hydrocyclones, filtered and dried.

Protein filtration and drying; The protein is also filtered and dried. The

products from the wet milling: 66% starch, 4% oil and 30% animal feed. Most of

the starch is converted into modified starches, sweeteners, alcohol and other

useful products

Dry milling

It consists of two types: degerming and non-degerming

systems. They produce maize meal, maize grits from hard starch and maize flour

from soft starch. Maize meal from non-degerming system has the germ thus a

shorter shelf life.

Degerming system

Cleaning and

separating

Tempering aims at removing the hull and germ from the

endosperm. The germ absorbs water faster than the endosperm thus it has

capacity of strength and elasticity. The last step gives moisture to the hull.

Degerming: the

tip, hull and germ are removed. Endosperm produces grits and maize four. The

degermer corresponds to the corrugated rolls of wheat milling.

Drying: the

degermed stock of 15-18% moisture is dehydrated to 12-13%.

Reduction and grading

Comments

Post a Comment